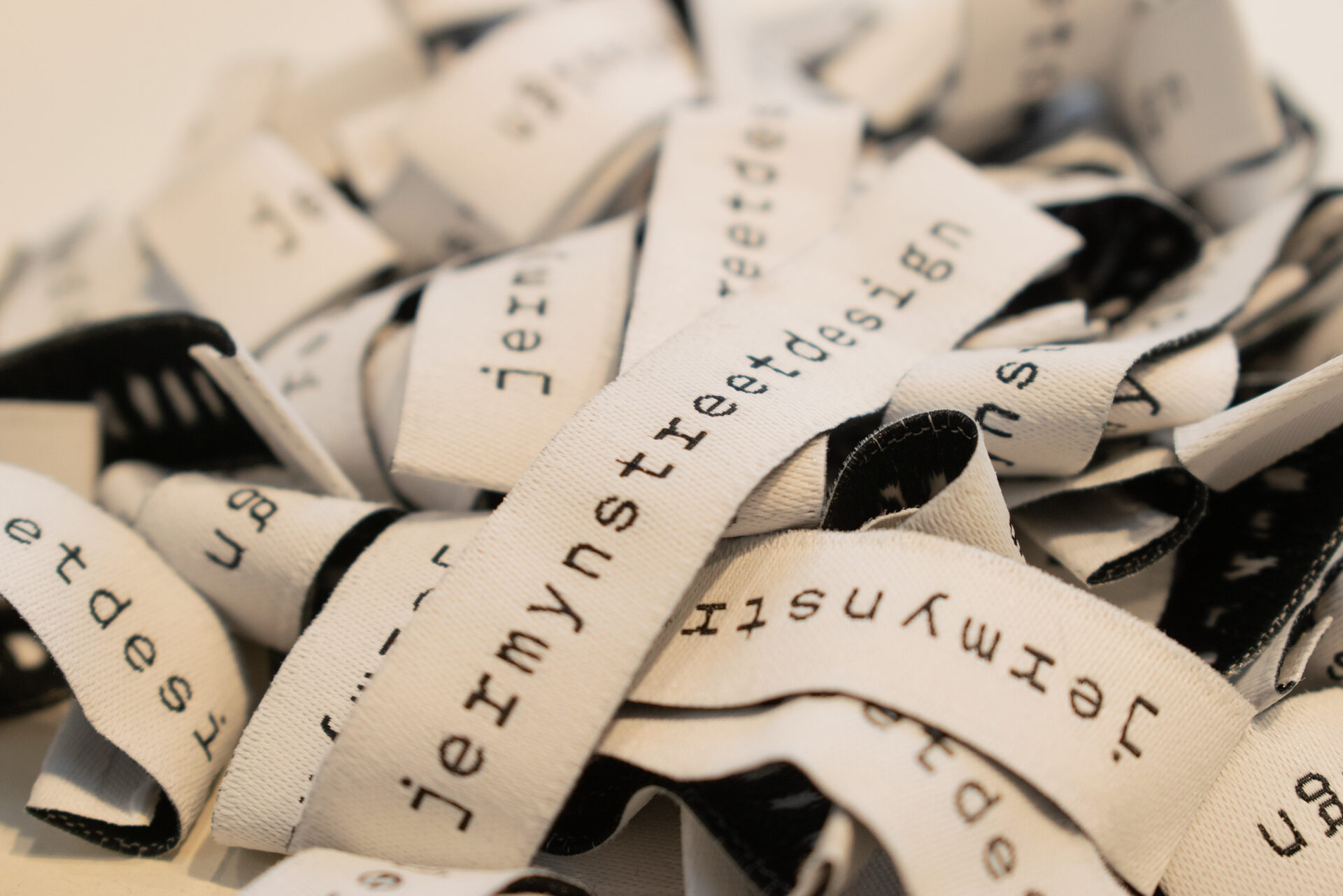

Leading Uniform Innovation: Introducing JSDLeading Uniform Innovation:

BESPOKE TAILORED UNIFORMS

With over 65 world-leading clients in more than 80 countries across the globe. At JSD, we understand that no two clients are the same, which is why we go above and beyond to deliver exceptional service tailored to your brand’s unique needs.

Innovation lies at the heart of everything we do. We pride ourselves on pushing the boundaries of creativity and design, ensuring that our custom uniform & corporate clothing reflects your brand identity but also sets you apart. Through wearer well-being, better brand experiences and operational efficiency, we build business value for clients throughout the lifecycle of clothes at work from research & design through manufacture to roll-out, predictive stock control & responsible end-of-life disposal.

OUR PROCESS

Creating, producing, and managing Clothes at Work needs to be a flexible process. Whether you are the individual end-wearer of a uniform, the uniform’s brand owner or responsible for your company’s international business operations and procurement – one size does not fit all. Check out Our Process page to learn more.

ABOUT JSD:

WE ARE PROUD TO DESIGN BESPOKE UNIFORMS.WE ARE PROUD TO DESIGN BESPOKE UNIFORMS.

Countries...

80+Since...

1981Wearer...

350kGarments Delivered...

565k pa